Detailed description

Main Usage:

Material is pushed by airflow, then it begins to be fluidized and mixed, becoming to be a fluidized status. But this state is irregular, and isn’t suffered from strict control. This is different from bottom spray and tangent spray. Liquid medium spray from top to bottom through spray nozzle; the fluid flow and material movement are in the opposite direction. The “liquid bridge” built by the surface strain of liquid medium, powder materials conglutinate with each other, the bulk enlarges continuously, thus to form granules, besides to be dried by hot air flow. This is called fluid bed spray granulating, fluid bed granulator in short. For the mixing, granulating and drying are completed in the same sealed container in one process, so we call it one process granulating.

The instant granules made by the machine, can be used for putting in the capsules and tabletting, so it’s the ideal choice for granulating, power mixing and drying in the industry of pharmaceutical, food, chemical, etc.

Main Usage:

Material is pushed by airflow, then it begins to be fluidized and mixed, becoming to be a fluidized status. But this state is irregular, and isn’t suffered from strict control. This is different from bottom spray and tangent spray. Liquid medium spray from top to bottom through spray nozzle; the fluid flow and material movement are in the opposite direction. The “liquid bridge” built by the surface strain of liquid medium, powder materials conglutinate with each other, the bulk enlarges continuously, thus to form granules, besides to be dried by hot air flow. This is called fluid bed spray granulating, fluid bed granulator in short. For the mixing, granulating and drying are completed in the same sealed container in one process, so we call it one process granulating.

The instant granules made by the machine, can be used for putting in the capsules and tabletting, so it’s the ideal choice for granulating, power mixing and drying in the industry of pharmaceutical, food, chemical, etc.

Specialty:

Because of using the state of fluidization to dry, the heat transmission of medium is fast;

Because of operation at hte condition of seal, there is no dust;

Because of using anti0static material as filter, it is safe in operation;

The equipment has no dead corner so it is easy to clean fully and there is no cross pollution;

It is in conformity with the requirements of GMP.

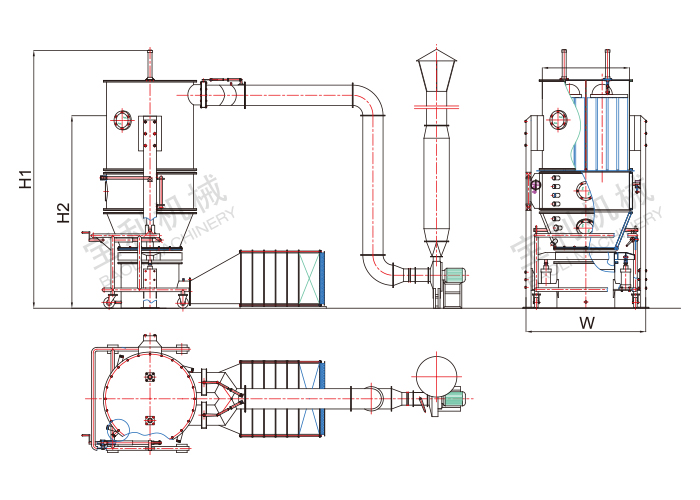

Technical parameter

| Model | Main Structural Dimensions(mm) | Volume | Volume of container |

Steam | Fan power | Compressed air | ||||

| Pressure | Consumption | |||||||||

| W | H1 | H2 | Φ | L | KG | Kg/h | Kw | Mpa | M³/min | |

| FL-5 | 1200 | 3760 | 2290 | 800 | 22 | 5 | 12 | 4 | 0.3-0.5 | 0.3 |

| FL -15 | 1200 | 3760 | 2290 | 800 | 45 | 15 | 42 | 5.5 | 0.3-0.5 | 0.6 |

| FL -30 | 1480 | 4150 | 2400 | 1000 | 100 | 30 | 70 | 7.5 | 0.3-0.5 | 0.6 |

| FL -60 | 1694 | 4600 | 2770 | 1200 | 220 | 60 | 141 | 11 | 0.3-0.5 | 0.9 |

| FL -120 | 1890 | 5100 | 3200 | 1400 | 420 | 120 | 180 | 18.5 | 0.3-0.5 | 0.9 |

| FL -200 | 2090 | 5330 | 3300 | 1600 | 670 | 200 | 282 | 22 | 0.3-0.5 | 1.1 |

| FL -300 | 2290 | 5200 | 3340 | 1800 | 1000 | 300 | 366 | 37 | 0.3-0.5 | 2 |

| FL -500 | 2300 | 5300 | 3360 | 1800 | 1500 | 500 | 451 | 45 | 0.3-0.5 | 2.4 |