Detailed description

Introduction

Double Shafts Paddle Mixer is a new type of high homogeneity mixer which makes material weightless during mixing. It is widely used in heavy bulk density, high viscosity material such as dry mortar, metal, rubber, mining, plastic, chemical, Metallurgy industry and to meet highest homogeneity.

Working principal:

Double Shafts Paddle Mixer have two axes of mixing interior rotates to different sides and paddles attached to the axes forms fluidized area by diffusing mixed materials to different directions according to stable apex speed. At this time, the movement of materials is concentrated on the higher center part from the bottom of mixer, and therefore, the effective volume of mixing room increases, and as the effective volume increases, the collision and rubbing between materials decrease. Also, as the contacting section between materials and the mixing room, there is no damage because of collision and rubbing, and on the other hand, mixer itself does not cause inner rubbing because of material, so it keeps the shape of particle, and as it does not press rotating object or vent-less etc., it prevents the leakage of materials on the seal part and proceed mixing. Like this, zero-gravity mixer became created the new concept of powder mixing by solving problems of eruption and leakage etc, as well as precision of mixing.

Introduction

Double Shafts Paddle Mixer is a new type of high homogeneity mixer which makes material weightless during mixing. It is widely used in heavy bulk density, high viscosity material such as dry mortar, metal, rubber, mining, plastic, chemical, Metallurgy industry and to meet highest homogeneity.

Working principal:

Double Shafts Paddle Mixer have two axes of mixing interior rotates to different sides and paddles attached to the axes forms fluidized area by diffusing mixed materials to different directions according to stable apex speed. At this time, the movement of materials is concentrated on the higher center part from the bottom of mixer, and therefore, the effective volume of mixing room increases, and as the effective volume increases, the collision and rubbing between materials decrease. Also, as the contacting section between materials and the mixing room, there is no damage because of collision and rubbing, and on the other hand, mixer itself does not cause inner rubbing because of material, so it keeps the shape of particle, and as it does not press rotating object or vent-less etc., it prevents the leakage of materials on the seal part and proceed mixing. Like this, zero-gravity mixer became created the new concept of powder mixing by solving problems of eruption and leakage etc, as well as precision of mixing.

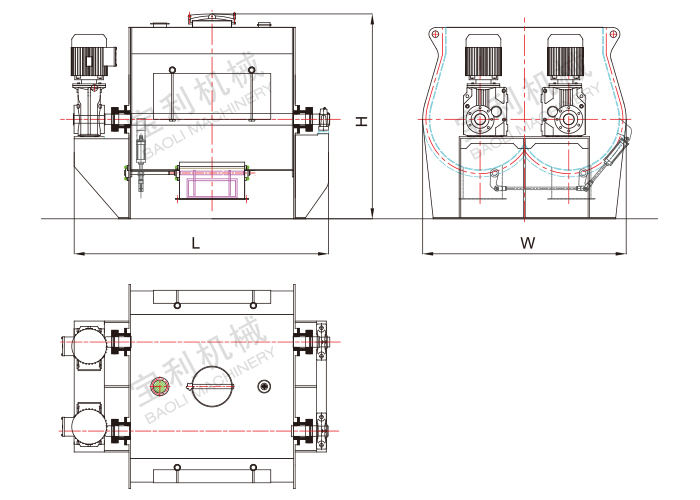

Technical parameter

|

Model |

Main Structural Dimensions(mm) |

Volume | Max loading | Speed | Machine weight | Total power | ||

| L | W | H | L | KG/Batch | Rpm/min | T | KW | |

| JB-300 | 1640 | 1000 | 1350 | 300 | 150 | 60 | 800 | 6 |

| JB-600 | 1915 | 1200 | 1560 | 600 | 300 | 43 | 1000 | 11 |

| JB-1000 | 2510 | 1400 | 1800 | 1000 | 500 | 43 | 1500 | 15 |

| JB-2000 | 2980 | 1700 | 1900 | 2000 | 1000 | 43 | 2500 | 22 |

| JB-3000 | 3160 | 1800 | 1950 | 3000 | 1500 | 43 | 2900 | 30 |

| JB-4000 | 3360 | 1900 | 2000 | 4000 | 2000 | 35 | 4100 | 37 |

| JB-6000 | 3640 | 2150 | 2350 | 6000 | 3000 | 35 | 6500 | 44 |

| JB-8000 | 4100 | 2400 | 2500 | 8000 | 4000 | 29 | 7500 | 60 |

| JB-10000 | 4320 | 2600 | 2600 | 10000 | 5000 | 29 | 8600 | 60 |

| JB-12000 | 5000 | 2650 | 2700 | 12000 | 6000 | 22 | 9800 | 74 |

| JB-15000 | 5000 | 2700 | 2800 | 15000 | 7500 | 22 | 11600 | 90 |

| JB-20000 | 5600 | 2800 | 2850 | 20000 | 10000 | 19 | 16400 | 90 |

| JB-30000 | 5800 | 2900 | 2900 | 30000 | 15000 | 16 | 23000 | 110 |