Detailed description

Working Method

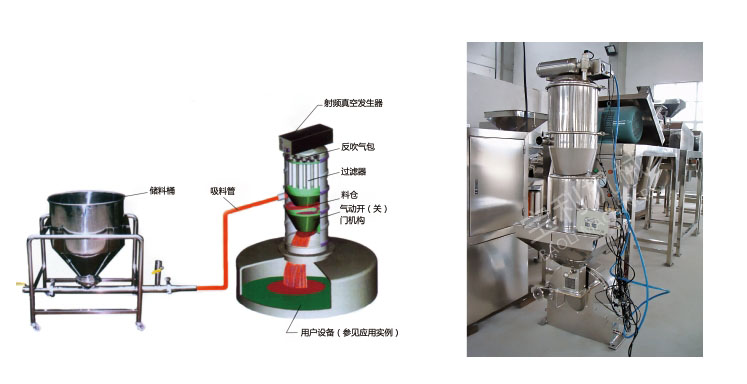

Pneumatic Vacuum Feeding Machine conveys materials at the use of compressed air through the vacuum generator to achieve high vacuum, it does not require mechanical vacuum pump, with the features of a simple structure, small size, maintenance-free, low noise, convenient control and elimination of materials static and in accordance with the GMP requirements etc. Vacuum generator generates high vacuum in order to enable delivery of materials to eliminate the stratification, and ensure homogeneous of mixture ingredients. It is the preferred equipment of mechanical automatic feeding device, such as pressure machine, capsule filling machitne, dry type granulator, packing machine, grinder, vibrating screen etc.

When supplying compressed air to the Vacuum generator, vacuum generators produce negative pressure on the formation of vacuum air flow, thus materials are sucked into suction Tsui, and form mist flow, and arrival on the chamber of feeding machine through suction tube. Filter separates materials and th air completely, when the hopper is filled with materials, the controller will automatically cut off the gas source and vacuum geerators stop working, at the same time hopper door opens sutomatically that materials fall into the hlpper of equipment. Meanwhile, compressed air clean the filter automaticlly through the pulse-jet cleaning valve. It will start up feeder automatically when the time is off or material level sensor sends out signals.

Vaccuum feeder generates vacuum (negative pressure) by Radio frequency generator, so vacuum feeder sucks materials from storage barrel into the bin through suction tube, then gas materials will be sparated through the filter, the time of feeding will be decided by controller. Pneumatic door-switch mechanism will open the door and put materials in ralated equipments when sucking finished. Back flushing device will blow the powder which is absorbed on the filter to clean away them, then the discharge door will be closed and next circulation begins.

Working Method

Pneumatic Vacuum Feeding Machine conveys materials at the use of compressed air through the vacuum generator to achieve high vacuum, it does not require mechanical vacuum pump, with the features of a simple structure, small size, maintenance-free, low noise, convenient control and elimination of materials static and in accordance with the GMP requirements etc. Vacuum generator generates high vacuum in order to enable delivery of materials to eliminate the stratification, and ensure homogeneous of mixture ingredients. It is the preferred equipment of mechanical automatic feeding device, such as pressure machine, capsule filling machitne, dry type granulator, packing machine, grinder, vibrating screen etc.

When supplying compressed air to the Vacuum generator, vacuum generators produce negative pressure on the formation of vacuum air flow, thus materials are sucked into suction Tsui, and form mist flow, and arrival on the chamber of feeding machine through suction tube. Filter separates materials and th air completely, when the hopper is filled with materials, the controller will automatically cut off the gas source and vacuum geerators stop working, at the same time hopper door opens sutomatically that materials fall into the hlpper of equipment. Meanwhile, compressed air clean the filter automaticlly through the pulse-jet cleaning valve. It will start up feeder automatically when the time is off or material level sensor sends out signals.

Vaccuum feeder generates vacuum (negative pressure) by Radio frequency generator, so vacuum feeder sucks materials from storage barrel into the bin through suction tube, then gas materials will be sparated through the filter, the time of feeding will be decided by controller. Pneumatic door-switch mechanism will open the door and put materials in ralated equipments when sucking finished. Back flushing device will blow the powder which is absorbed on the filter to clean away them, then the discharge door will be closed and next circulation begins.

Technical parameter

|

Model

|

QVC-1

|

QVC-2

|

QVC-3

|

QVC-4

|

QVC-5

|

QVC-6

|

|

Capacity (kg/h)

|

350

|

700

|

1500

|

3000

|

6000

|

9000

|

|

Ari Consumption (L/min)

|

180

|

360

|

720

|

1440

|

2880

|

4320

|

|

Air Pressure Supply(Mpa)

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

0.4-0.6

|

|

Overall Size

|

φ140×560

|

φ213×720

|

φ290×850

|

φ420×1150

|

φ420×1150

|

φ420×1350

|

|

Suction pipe(mm)

|

φ51

|

φ51

|

φ64

|

φ64

|

φ64

|

φ64

|